Fiber fusion splicer “welding” optical fibers under a microscope!

2023-11-01

This is a video of an optical fiber fusion splicer "welding" optical fibers under a microscope. It is easy to splice one fiber, but it is amazing to splice 12 fibers at the same time without seeing any weld marks! Optical fiber is a glass fiber thinner than a human hair, which uses the transmission principle of "total reflection of light". Plasma welding is used to weld optical fibers. After discharge heating, the glass is melted and joined together flawlessly.

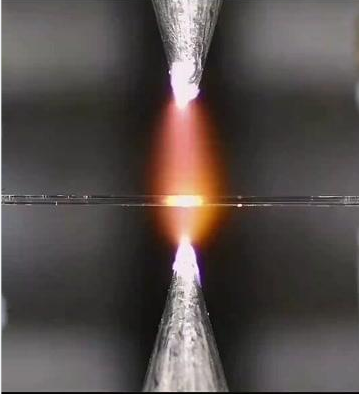

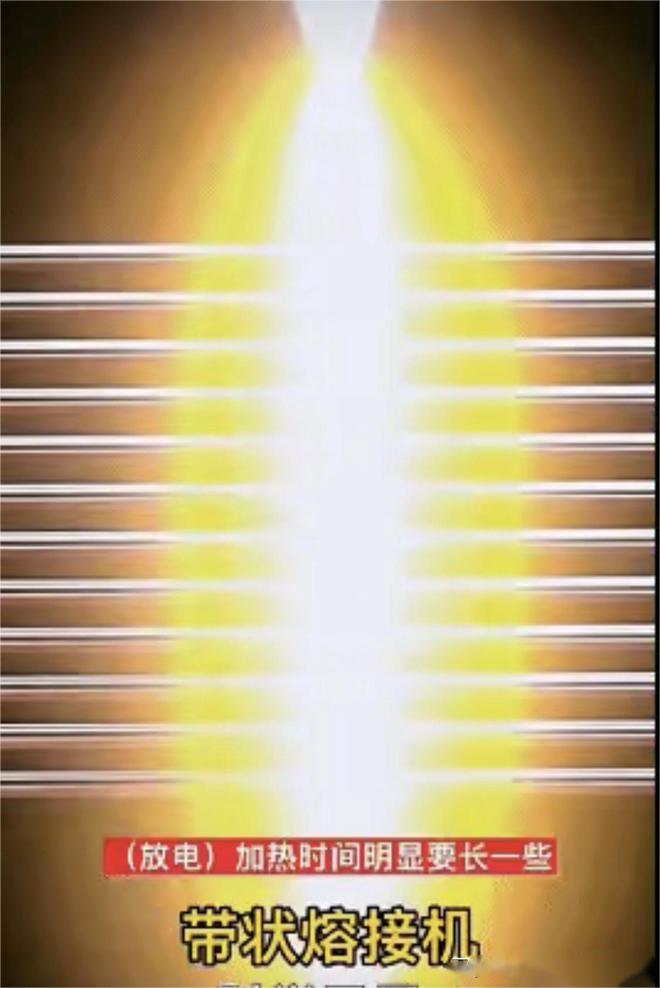

The picture shows the working state of a single-core fusion splicer under a microscope. The ribbon fusion splicer welds 12-core ribbon optical fibers, and the discharge heating time is longer. The principle of welding optical fiber is to put it simply: melt two glass filaments and then connect them together.

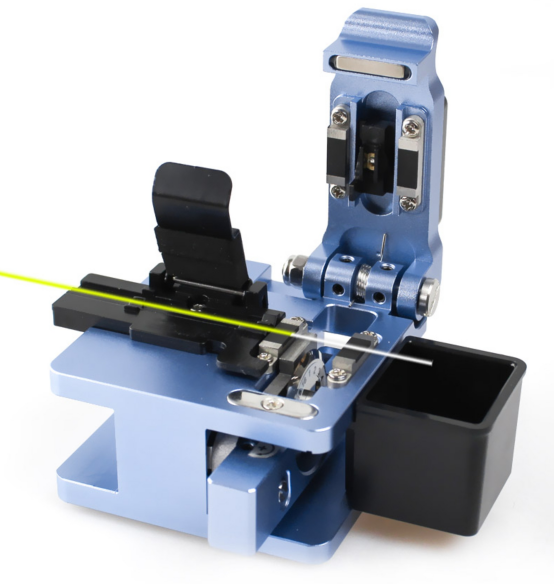

The principle of fiber fusion splicing is to use the lateral imaging alignment method to align two optical fibers, perform image processing on the side imaging of the optical fiber, find the characteristic value related to the fiber position or azimuth angle as the independent variable, and inversely deduce the dependent variable, and then The rotation or movement of the optical fiber is controlled by a precision motor to meet the requirements before splicing.

Then we use the preheating fusion method that everyone is currently using to weld. Before welding, we must clean it and there should be no dust. Then pre-discharge the fiber end face to preheat and shape it. Finally, in the main discharge environment, let the fiber end face be preheated and shaped. One optical fiber moves axially to complete the splicing of two optical fibers and form an optical fiber splicing point. While using a high-voltage arc to melt the sections of two optical fibers, a high-precision motion mechanism is used to gently advance the two optical fibers into one.